The Next Big Thing is “Product Reliability"

- People really care about reliability of Products.

- This is something every one expects but since the technology is unable to provide, product developers are unable to offer.

- There are So Many Issues distracting the working of current electronics like Noise and designers use current electronics with different methods to achieve reliability as much as they can but unable to take guarantee on product reliability.

- The New Products need Reliable electronics to provide stable and reliable services to users.

- Due to unreliable electronics, lots of products are chocked and does not sell as people does not believe them and dose not use them to a extent of daily life.

- Everyone needs reliable product despite of the usage.

- High end products want to take full control of application but innovation on design is not blocking them to be placed to consumers. It is reliability of the products.

The Working Environment of Electronic Products

Following are some of the different type of Hazards which distract Electronic Circuits –

- Ambient Noise

- Power Quality Degradation Noise

- High Power Noise

- Railroad and Mass Transit Noise

- Medical equipment Generated Noise

Ambient Noise/ Ambient EME is composed of numerous sources of which the most significant are –

- Television transmissions

- Solar Magnetic Storms which peak on a eleven year cycle.

- Lightning which occurs as a very high voltage and high current event

- Utility power grid transmission lines.

- Other ambient EME sources include airport radar, telecom transmissions, electrostatic discharge (ESD), and white noise.

- Some other major product and systems as emissions sources include switching mode power supplies, arc welders, motor bushes and electrical contacts.

Effect of Ambient Noise/ Ambient EME –

- It can affect sensitive electronic equipment Internal Voltage and Line Voltages.

- In the case of the effects of ESD on sensitive electronic systems, it can cause upsets, burn outs, and latch-ups in these units.

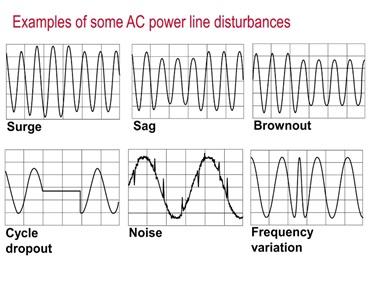

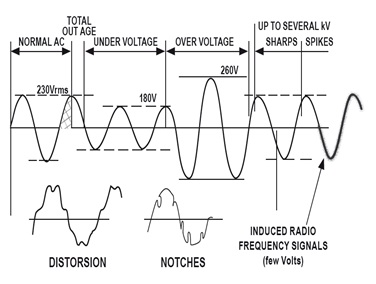

Power Quality degradation factors can affect the operation of equipment that is powered by a mains power source. These mains degradation factors include:

- Voltage surges, sages, dips, spikes, and high and low voltage

- Brownouts and blackouts

- Power line faults

- Electrical Fast Transitions (EFT)

Effect of Power Quality degradation Noise –

- Power Quality distortions and transient that are present on the power main systems can affect the normal operation of the equipment to that it supplies power.

- Transits such as power surges are capable of destroying interface electronic circuits. EFTs can cause electronic circuit upset conditions.

High Powered Electromagnetic Pulses threats which are intended to disable electrical and electronic equipment.

Currently, existing HEMP devices include the following:

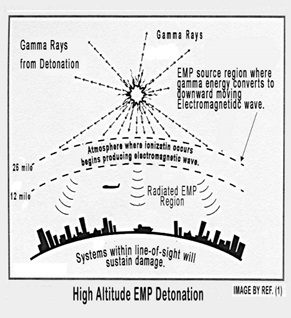

- High Altitude Electromagnetic Pulse (HEMP)

- High Powered Microwave (HPM)

- Intentional Electromagnetic Interference (IEMI) source

Effect of High Powered Electromagnetic Pulses –

- High powered electromagnetic sources can totally destroy an electrical and electronic equipment’s function.

- High-Altitude Electromagnetic Pulse (HEMP) is a near-instantaneous electromagnetic energy field that is produced in the atmosphere by the power and radiation of a nuclear explosion, and that is damaging to electronic equipment over a very wide area, depending on power of the nuclear device and altitude of the burst.

- High-Power Microwave (HPM) electromagnetic energy can be produced as a near-instantaneous pulse created through special electrical equipment that transforms battery power, or powerful chemical reaction or explosion, into intense microwaves that are also very damaging to electronics, but within a much smaller area.

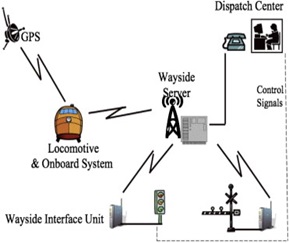

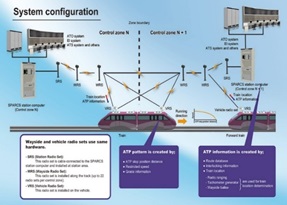

Railroad and Mass Transit Systems have some unique types of EMI source problems. These include:

- Train signaling systems and their associate Computer operating codes.

- Third rail shoes arcing broadband emissions

- Train control system’s emissions.

Effect of Railroad and Mass Transit Systems Noise –

Railroad and Mass Transit Systems have one primary source of EMI and that is the transit and railroad engine’s propulsion systems, which operates with high voltages, currents, and magnetic field levels.

- They have been known to affect other facilities that contain sensitive electrical equipment that are located near the railroad or mass transit systems right away.

- These propulsion systems have had EMI associated problems with other elements of their systems.

- Train control electronics can be affected by EMI sources such as third rail and other broadband frequency arcing sources if they are not adequate designed for EMC.

Medical equipment utilized in medical facilities has numerous EMI sources. Some of the more prominent of these are listed below:

- Life support equipment such as ventilators, cardiac defibrillators, infusion pumps, etc.

- Patient telemetry and assistance equipment which includes electrocardiographs and motorized wheelchairs.

- Electrical surgical units and their associated support equipment.

- Magnetic Resonance Imagine (MRIs) system.

- X-ray units, both therapeutic and diagnostic

- Gamma Beam Electron Accelerators and Therapeutic equipment

Effect of Medical Equipment Generated Noise –

- Medical equipment and facilities sources include patient monitoring systems

- Those are very susceptible to EMI interactions.

- The human body signals that they monitor are very weak.

- They are measured in unites of microvolts and micro-amps.

- Among other devices that are susceptible to EMI are hearing aids, wireless patient monitoring systems, magnetic resonance imaging systems, implantable cardiovascular devices, drug pumps, and portable diagnostic meters.

- As new technologies are developed and enter the marketplace at a fast pace the list will grow.

GreenIPCore Robust, Stable and Reliable Technology.

GreenIPCore High Stable, Fault Resilient Technology Innovation

To Give you feel of technological innovation we present, Please look into the Video Presentation of technology Comparison we present to you.

Presenting High Stable, Fault Resilient Technology for your products

GreenIPCore Presents Fault Resilient Soft Digital IPs for SOC’s and Fault Resilient Soft Digital Security IPs for Security infrastructure used inside Secure SOC’s. We also Offer Development of Custom IP Development as per your application needs. Please look into our Portfolio IPs for more details into it.

Some Conventional, Not Much Reliable, Methods

Below are methods used to isolate circuits, identify errors and keep them running bug free but none of them is able to guarantee the application reliability and provide dependent electronic products.

- Some External protection Methods –

- Metal Shields

- Coating Paint

- Some Internal Chip methods –

- Lock Step – Detects Error but generate chip wide reset.

- Triple Vote, Multi Vote, De-bounce etc in Hardware – Increases gate count a lot, still application misbehaves.

- Software methods

- Software Redundancy

- Physical Library Methods.

- Redundancy implanted in Physical Library.

Still with all these methods, the application stability and reliability is not guaranteed.

Some Current External Protection Methods –

Metal Shield is good option but Noise can enter from different other paths like –

- Power Lines.

- Connection Lines.

- Temperature sudden variations

- Cannot be Complete “Faraday Cage” as there are lots of inputs coming from outside carry Different kind of Noise Signals.

Not all kind of Noise travel from metal paths. Noise from –

- Magnetic Sources like magnetic couplings and resonance can generate currents in remote wires entangled.

- Not all type of Radiation be blocked by shields.

This all makes a possibility of failure in product randomly.

Another non relevant drawback is increase in weight.

Heavy Metal Paint is good option but Noise can enter from different other paths like –

- Power Lines.

- Connection Lines.

- Temperature sudden variations

- Cannot be Complete farad cage as there is always space open from substrate within the boards.

- Magnetic Sources like magnetic couplings and resonance can generate currents in remote wires entangled.

- Not all type of Radiation be blocked by Heavy metal Paint shields.

This all makes a possibility of failure in product randomly.

Another Non Relevant Drawback is Very Costly Paints, can effect product price.

Some Current Internal Protection Methods –

Lock Step Method uses two core of the same type working in parallel all the time, having same inputs and compares all the outputs. This method is good to identify a error in operation of logic but It has following issues –

- It cannot fix the Error.

- The only reaction system has for lockstep error is reset the complete chip.

- Application working on this is highly suspected to have resets incase there is any corruption.

- Realtime applications like Automotive, Aerospace, Drone etc.. should not be built using this as the chip can reset at any wrong time.

- New Application like Autonomous engineering, Autonomous Driving etc should not be build using this as they need to be functional and working perfect all the times.

Another Non Relevant but important Drawback is this method doubles the gate count and double the power.

Triple vote, Multi-Vote, De-Bounce, ECC, Parity and other minor logic used today are not able to develop a reliable product.

These methods are applied on boundary, interfaces and some portion of Application but the entire Application is built of functional logic inside and noise can effect any logic not just periphery.

End-to-End ECC is able to protect Data and control flowing from one IP to another and stored data in memory but cannot protect against Logic. Also, the protected bits are so less in this method that this protection does not able to resist against Electromagnetic Noise and Other environmental hazards.

These methods gives very minor protection and Complete application and product working remain Unreliable.

Another Non Relevant but important Drawback is this method gate count and the dynamic/ static power consumption increases a lot.

Software Methods for Stability

Software Methods

Software uses methods like

- De-bounce implementation while reading information and status from Hardware.

- Multi Checks for old conditions with new conditions.

- Storing same data at multiple places.

- Calculating Checksum, CRC and ECC for different data.

None of the Method used are able to identify if hardware itself is misbehaving and giving wrong results making software blind.

Another Non Relevant but sometime important Drawback is this method is –

- Software execution set size increases a lot making entire application to consume more MIPS which result in

- bulky Software Routine,

- Large application code size,

- increase in memory consumption size,

- increase in Boot ROMs and Boot Images

- Increase in Library Sizes.

- This Make complete Product LAG and Operate Slowly.

Physical Library Methods for Stability

Physical Level Library improvements Methods

There are So many methods used on physical library like

- Using More HVT Cells.

- Implement redundancy like triple vote in physical library.

- Using Overdoped Cells.

- Balancing Physical Lines to reject Noise impacts.

- Using logic duplication.

- etc..

None of the Method used are able to fully guarantee the working of application and ensure that none of the Noise has pass through and impacted the hardware to misbehave.

Another Non Relevant but sometime important Drawback is this method is –

- Need Full Custom ASIC somtime.

- Increase in Silicon Area

- Increase in Silicon Power.

- Increase the Timing Paths making more use of HVT Cells which again result in continuous consumption of more Power.

About GreenIPCore Technologies

GreenIPCore is a leading IP Core Provider to enable Reliable Product Line.

Achievements

GreenIPCore has Proven High Stable, Fault Resilient Technology across Different Semiconductor Platforms. World-class leadership and engineering teams with expertise in Fault Resilient Technology, High Performance, Security, deep-learning and AI

Technology Patent

GreenIPCore Holds 2 Patents in High Stable, Fault Resilient Technology.

Contact Us

Want to accelerate your project with GreenIPCore innovation? We provide Wide Range of Safety and Fail Safe IPs to enable Product for Automotive, IIOT, Security and AIML. Let us help you discover the power of our scalable and efficient technology.

Partner for Early Access

At GreenIPCore, we’re always working on what’s next. Partner with us to be the first to learn more and test our next generation designs with Early Access.

805, 8th Floor, OM Tower, Alpha Commercial Belt, Greater Noida, India, Pin: 201310

email : – start@greenipcore.com

Mobile: – +91 9821330671

Privacy Policy | Disclaimer | Press Release